It can be a challenge to select the proper filter media. With the large number of possible applications and the growing requirements of the market – and ever changing legislation – more intelligent solutions are required more than ever before. Industec’s expert team offers professional advice to help your company find the best solution for all your application needs.

Using Gutsche® high performance textiles, quality filter bags are individually manufactured on automatic tubing lines. Each filter is tailored to suit your individual process requirements.

We can manufacture the full range of filter bags in a comprehensive range of fabrics to suit all OEM designs including but not limited to Luhr, Mikropul, Lurgi, Flakt, DCE, HPS, Aerolux, Airsystems, Filtaire.

Our specialised fabrics are constructed from a range of fibers suited for low and high temperature applications. These material fibers include:

Industec supply a wide range of high quality filter cages to suit all OEM designs. We can also custom make to suit each end user’s specification. Cages range from mild steel, galvanized wire, high temperature powder coatings or stainless steel.

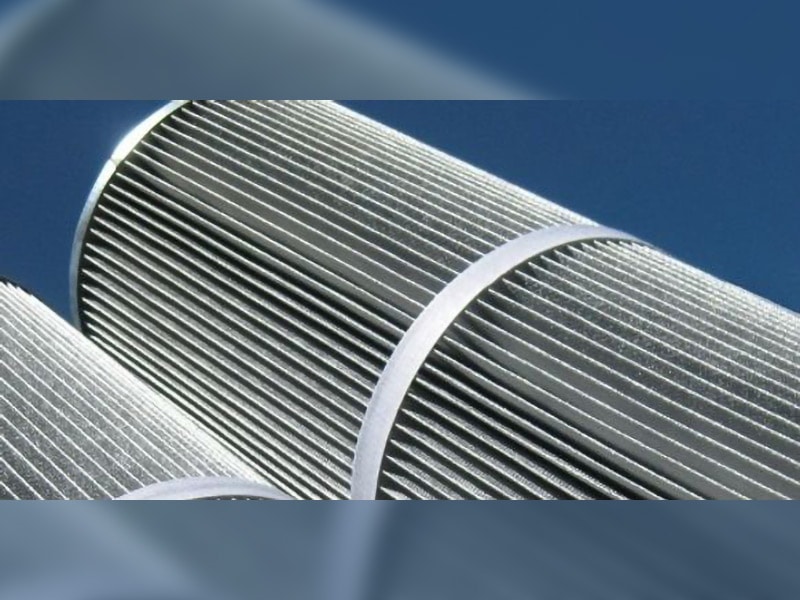

In certain applications, filter cartridges and pleated bags can be an excellent choice as they offer a higher filtration area compared to the conventional filter bag.

Our filters are available in 1 or 2 piece designs, to suit both low and high temperature applications. Our materials are engineered to filter very fine dust we are available in spun bonded polyester, with oleophobic treatment, Nomex, 100% PTFE and with ePTFE membranes.

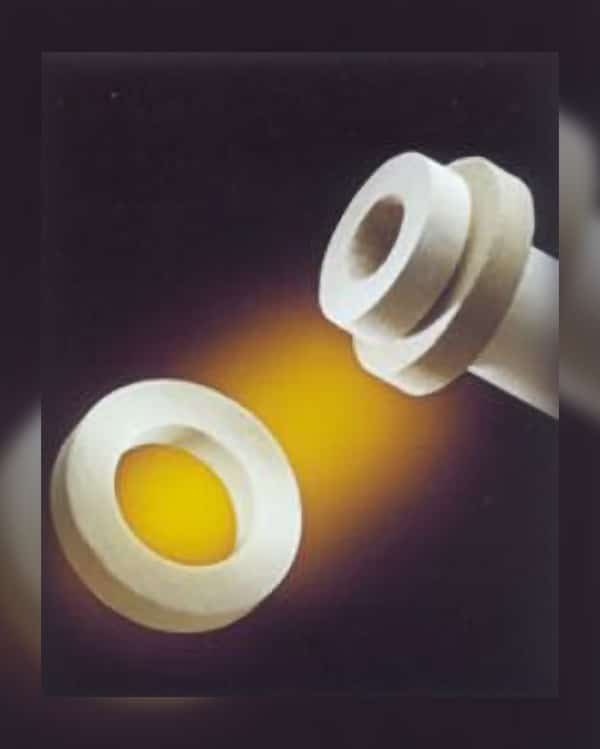

TENMAT high temperature filters are made from inorganically bonded granular minerals, providing more strength than any other commercially available filter. TENMAT hot gas filter elements are filter tubes developed for operating temperatures up to 1000 °C.

TENMAT manufactures a wide range of element designs in a choice of exonerated refractory materials tailor-made to customer requirements. Without the use of asbestos or ceramic fibres, TENMAT elements comply with the highest environmental emission standards worldwide.

Atmospheric Pollution Control

In Line Equipment Protection

©2025 FilterCare Australia Group

Web Design by MyWork